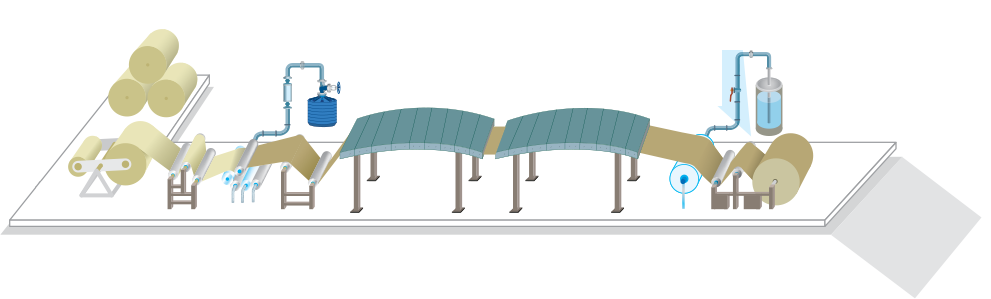

Manufacture process

You can watch actual process photos by clicking ‘See more.’

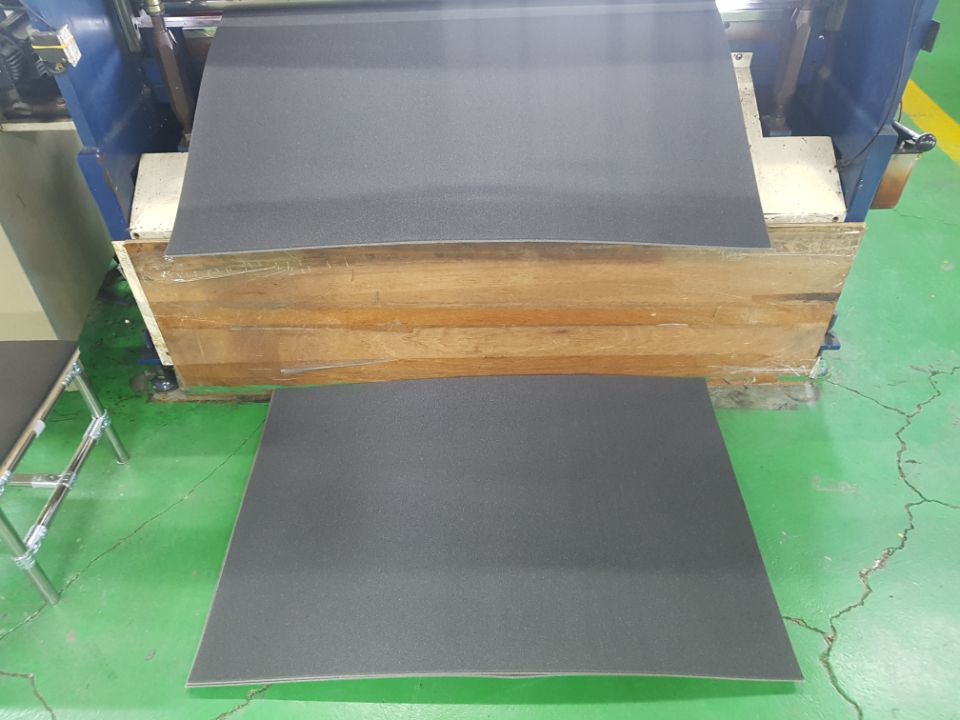

01. Raw Material Storing

See More

Raw material storing (stencil paper storing)

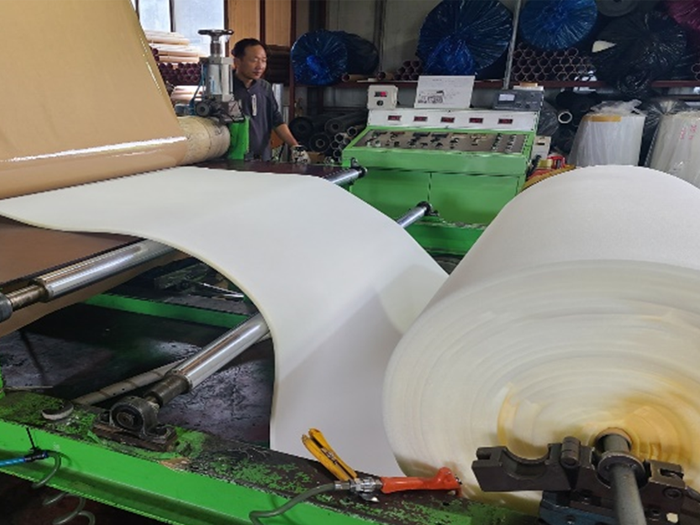

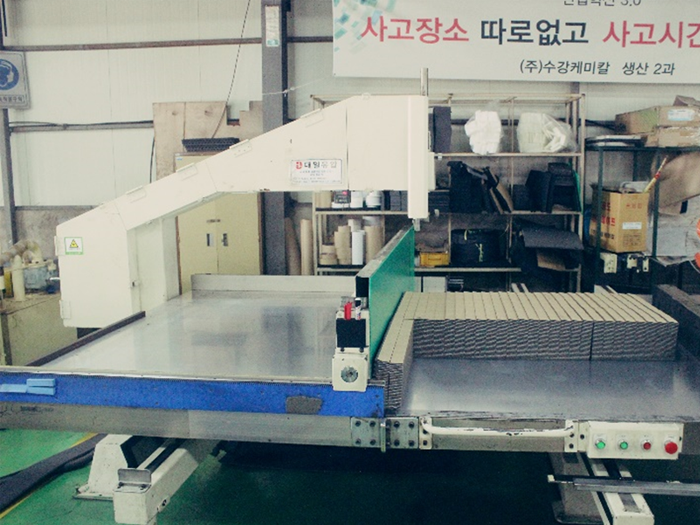

02. Unwinder

See More

This unwinding process is a turret type.

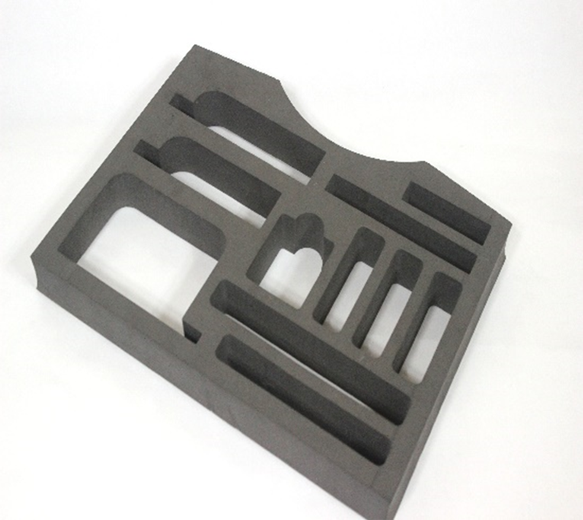

03. Silicon Application

See More

Silicon is applied on paper using a coating roller.

04. Hot Air Drying

See More

Silicon is applied on paper using a coating roller.

05. Cooling Process

See More

After drying the silicon on the paper so that it transfers well to the paper, it is cooled with cooling water.

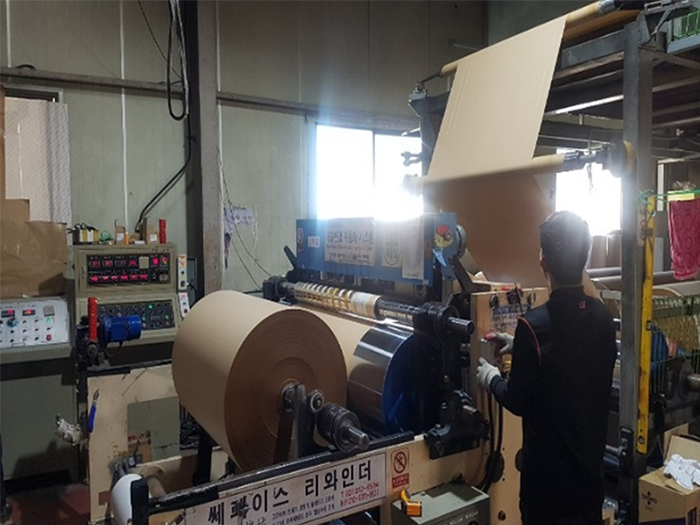

06. Rewinder

See More

This rewinding process to rewind the paper which has been cooled is a surface type.